What is hook and loop ?

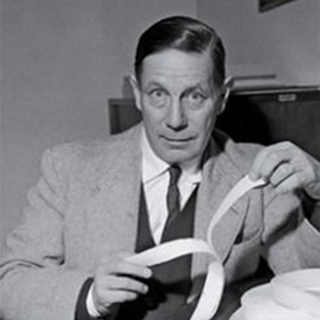

Who invented hook and loop?

The Swiss engineer, Georges de Mestral, is the inventor of the hook and loop fastener, better known as "velcro". During a hunting trip, he noticed that cockleburs had clung to his velvet pants and to his dog's hair. This inspired him to create Velcro®, composed of two strips of fabric, one with hooks, the other with loops. The name Velcro® comes from the French words for velvet (“velours”) and hook (“crochet”).

At the time, how could he have imagined that this discovery would become one of the fifty most important inventions of the 20th century?

In 1958, Jean Billarant, founder of APLIX, establishes Velcro France to produce and sell Velcro® brand hook and loop fasteners under a license from the Swiss Company Velcro S.A. created by George de Mestral. He was one of the first to produce and market this new fastening system in the world.

In 1976, after patent expiration, Velcro France ceases affiliation with Velcro S.A., changes its name to APLIX, and adopts the aplix® trademark to identify its hook and loop fasteners.

Hook and Loop closure is a perfect example of biomimicry!

Originally, the velcro hook and loop closure was inspired by nature. It is a perfect example of biomimicry, a science that copies nature to design new technologies!

Burdock is a plant that propagates its seeds through burs that cling to everything they touch. George de Mestral, a Swiss engineer, was intrigued by these cockleburs that stuck to his dog's fur after they had been out on a ramble. This inspired him to create Velcro®, composed of two strips of fabric, one with hooks, the other with loops. The name Velcro® comes from the French words for velvet (“velours”) and hook (“crochet”). The velvet covered with tiny plastic loops mimics the animal fur and the hooks mimic the cockleburs.

How do hook and loop fasteners work?

The hook and loop fastener is an adjustable closure obtained by pressing two parts together. The gripping part penetrates the loop part. On opening, the hooks open and release the loop.

The closure performance in terms of longevity, grip, and resistance to opening varies according to:

- the shape of the gripping element: hook, mushroom or harpoon. Various technologies are used in their manufacture weaving, extrusion or injection moulding.

- the construction of the loop: density, texture and size of filaments. Various technologies are used in their manufacture weaving, knitting or non-woven.

Depending on the requirements of your application, APLIX can offer a hook & loop combination which will give you the best results.

Discover APLIX’s hook and loop products

Our hook and loop tapes are an alternative to traditional fastening and closing methods. They are very easy to fasten and offer amazing adhesion performance!

APLIX has developed a wide range of high quality hook and loop tapes that can meet many application criteria such as fastening strength for heavy or light objects, longevity up to 10,000 cycles, fire resistance, UV or moisture resistance... We also offer a range of very soft knitted and non-woven products, to provide comfort in markets such as diapers and medical applications.

In addition to traditional textile products, APLIX offers miniaturized plastic products, very soft non-woven products and elastic stretch products.

Products by needs

- Textile hook and loop

- Plastic hook

- Hook to hook closure

- Light weight loop

- Stretch laminates

- Fabricated products and coatings

Products by brand

- DecoGrip by Aplix®

- Easylock by Aplix®

- Intermold®

- SoftFit by Aplix®

- SoftGrip by Aplix®

- SoftLoop by Aplix®

- TexLoop by Aplix®